Hidden signs that your organisation is understaffed

Understaffing can put your organisation under pressure, often without being immediately noticeable. Deadlines start slipping, customer satisfaction declines, and productivity takes a hit. Recognising the right signals is essential to act quickly and prevent further impact.

Understaffing often creeps into your organisation slowly. At first, the signals still seem harmless: here and there a missed deadline, a bit more stress in the team, a few small mistakes. But over time, a pattern emerges: employees become exhausted, quality drops and customers notice something is off. Understaffing is rarely a momentary issue — it is a structural imbalance between what needs to be done and how much capacity is available.

The good news? Understaffing can be recognised. Once you know what to look for, you can intervene faster and prevent damage.

What is understaffing?

Understaffing means that your organisation does not have enough capacity to carry out the work efficiently, safely and with the necessary quality. This may be due to a shortage of staff, but just as often because workload increases while hours or qualifications stay the same. Teams are expected to do more than is realistically possible, leading to higher work pressure, overtime and declining motivation.

The impact is widespread: service quality drops, waiting times increase, employees become overstimulated or go off sick, and there is little room to look ahead or improve. Understaffing is therefore not just a staffing issue — it is an operational risk.

The most important signs of understaffing

1. Deadlines are repeatedly missed

When tasks take longer and longer, projects get delayed or the team keeps “putting out fires”, capacity is no longer aligned with workload. Lack of time becomes a structural pattern rather than an exception.

2. Employees become exhausted or mentally disengaged

Fatigue, irritation and tensions within the team are classic consequences of structural overload. Over time, this leads to rising sickness absence and even burnout.

3. Quality drops and errors increase

Rushed work creates mistakes: in administration, production, customer contact or care. Not because employees are incapable, but because they simply are not given the time.

4. Stress and turnover increase

Understaffing almost always leads to higher turnover. People leave not because they cannot do the job, but because they no longer *want* to do it under those conditions.

5. You cannot anticipate or look ahead

Understaffing makes an organisation reactive. Teams focus purely on getting through the day. As a result, there is no space for:

- capacity management

- forecasting

- preparing for seasonal peaks or busy periods

- annual and holiday planning

- improvement projects

- training and development

- process optimisation

Temporary pressure (holidays, illness waves, changing demand) then turns into mini-crises — simply because there is no buffer left.

How to recognise understaffing

You don’t recognise understaffing only by how busy the workplace feels. You recognise it mainly by patterns. The first signs are subtle, until suddenly they are impossible to ignore. These are the key ways to detect understaffing early:

1. Look at your operational KPIs

Numbers reveal a lot. When these rise, it almost always indicates a structural mismatch between demand and capacity:

- higher error rates

- declining productivity per team

- rising sickness absence

- more overtime

- increasing turnover or internal shifts

These are clear symptoms of teams that have been working at their limits for too long.

2. Listen to employees — they feel it first

People on the floor often experience understaffing weeks before it appears in reports. Watch for:

- recurring comments about workload

- not enough time to complete tasks

- less space for consultation or support

- increased tension in the team

Regular check-ins or short pulse surveys provide faster insights than detailed HR reports.

3. Watch customer, citizen or client feedback

When demand rises but capacity does not follow, that becomes visible externally:

- longer waiting times

- more mistakes or complaints

- lower satisfaction scores

- missed deadlines or delayed files

External feedback is often the most honest reflection of internal pressure.

4. Analyse your planning — not just the roster, but the requirements

Understaffing doesn’t only show through empty shifts. You’ll notice it especially when rosters:

- barely come together structurally

- depend on goodwill or improvisation

- have no buffer for illness or absence

- offer no margin for unexpected events

Even with full attendance, you can still be understaffed when demand exceeds capacity.

5. Look at the predictability of your operations

Teams that constantly improvise, take ad-hoc decisions or reshuffle at the last minute? Those are almost always teams working too tightly. Understaffing makes your organisation reactive — and you see that in the daily chaos before you see it in the numbers.

How software helps prevent understaffing

Many organisations only recognise understaffing once it is already painfully noticeable: chaos, delays, rising sickness absence. Not because they do not *want* to see it, but because they lack real-time insight into capacity and qualifications.

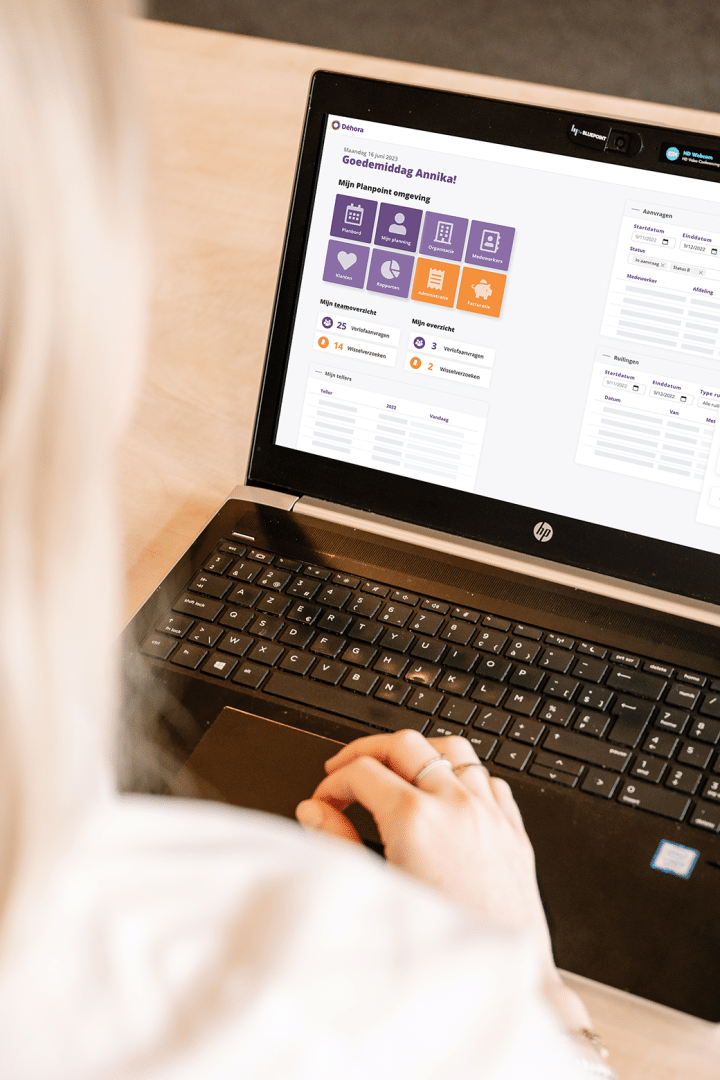

Workforce management software like Planpoint finally makes that visible. It shows not only who is scheduled, but what is needed for a shift to run safely, stably and with quality.

1. Real-time insight into capacity and staffing

Preventing understaffing starts with visibility. Planpoint shows in a single screen how many people you need, which qualifications are required, which activities must be staffed *and* whether your planning meets those needs.

This insight is built on staffing requirements — specific needs you define per day, shift or period. You instantly see where risks appear and where the planning is correct.

2. Balanced workforce rosters

Planpoint starts not from availability but from the work that must be done. The system takes peaks, tasks, qualifications and employee capacity into account, creating realistic and workable schedules that prevent overload.

3. Planning across departments

You don’t need to solve understaffing within one team. Planpoint shows who can be used elsewhere, which qualifications are available and who can step in. This allows you to cover shortages quickly without improvisation.

4. Fair distribution of shifts

Automatic schedule proposals ensure a balanced distribution of work. No more “the same people always filling the gaps”, but a fair system that takes workload and preferences into account. This brings calm and reduces absenteeism.

5. Better management of last-minute changes

Illness, absence or unexpected pressure are part of reality. Planpoint immediately shows which shift becomes vulnerable, which qualifications are missing and who can jump in. You adjust schedules in real time — without guesswork or calling round.

Tackling understaffing starts with insight

Understaffing rarely appears overnight. It grows when you lack insight into demand, capacity and qualifications — or when rosters depend too heavily on goodwill and ad-hoc solutions.

Planpoint makes these patterns visible and manageable. With real-time insight, strong schedules, fair distribution and quick adjustments, you stay in control of capacity and keep your operations stable day after day.

Experience Planpoint in action.

Find out how our platform can elevate your workforce planning. Schedule your free demo now.