Hilaire Van der Haeghe NV

Discover how the Hilaire Van der Haeghe Group uses Planpoint for better scheduling of technicians, customers and materials.

Smart scheduling of engineers and equipment

To sustain consistent growth, Hilaire Van der Haeghe urgently needed a modern workforce management system, with a connection to its order system.

A leading family business

Hilaire Van der Haeghe is a Belgian family business – the fourth generation already – with 120 years of experience, including more than 80 years in agriculture and the green sector. The organization is exclusive importer of premium brands such as Fendt, Amazone, Iseki, Walker, TS, Gianni Ferrari, Ferris, Snapper, Simplicity, Köppl, Holder, Yale, …

HH’s equipment includes various machines for agriculture, goods handling, parks and gardens: tractors, seeding and tillage machines, sprayers, combines, chippers, forklifts, self-propelled lawnmowers, sweepers, electric trucks and many more.

Since its founding in 1898, the organization has experienced consistent (international) growth. Today the working area of HH covers the entire Benelux, and beyond. The organization also has ambitious expansion plans for the coming years. But premium brands naturally demand premium service. And that can only be achieved with good organization and planning of all supporting services. This is precisely where HH faced a challenge.

What was Hilaire Van der Haeghe up against?

To service all its equipment, HH can count on an extensive and experienced team of technicians. And this for four different teams. However, it is not easy to keep a constant overview of all equipment, its maintenance, its location, any repairs, which technician is present for which job. In addition, some devices are outsourced for demonstrations, which makes planning quite complicated.

“To keep our service at a consistently high level, it is essential to know where which equipment is located. And in what condition, but also who needs what when, in order to deploy everything on time – and in top condition. Equipment, demos and technicians have to perform optimally. And that is not easy,” says Kristof Van Braband, Project Manager Hilaire Van der Haeghe.

For scheduling technicians and equipment, HH used Excel worksheets, Navision, Whatsapp, Outlook calendars and various mailboxes, among others. Each team worked with different systems. This made it very difficult from a business perspective to have an accurate picture of the planning throughout the organization. In addition, planning meant a lot of manual work: creating work schedules, communicating to technicians and customers, making substitutions or changes, scheduling orders, etc. In short, planning was quite complex, error-prone and time-consuming.

With future growth in mind, it became clear that this needed to be done differently. So at some point, HH decided to enlist professional help. The goal was to optimize the planning of technicians and equipment in one user-friendly system. Hilaire Van der Haeghe looked for and found a new planning software.

Solution-oriented approach

Several parties came up in that search. In the end, HH chose Planpoint. Planpoint focuses on the most efficient use of manpower and equipment.

The intensive collaboration began with preparatory discussions, concrete instructions, an overview of desiderata, timing and specifications that were both feasible and affordable. Some details, such as the presence of maps to optimize technicians’ journeys, were useful but not necessary; others were essential: think of the possibility for technicians to quickly transmit images remotely. Priority here? Avoiding or, even better, preventing machine downtime.

“What we immediately noticed and liked about Déhora was their straightforward approach. You immediately felt that they had both feet in reality. They had empathy and understood the real needs. The aim was to arrive at an accessible system that people could work with with a minimum of actions,” says Kristof Van Braband. “What we particularly appreciated throughout this process was their solution-oriented approach.”

A sustainable future

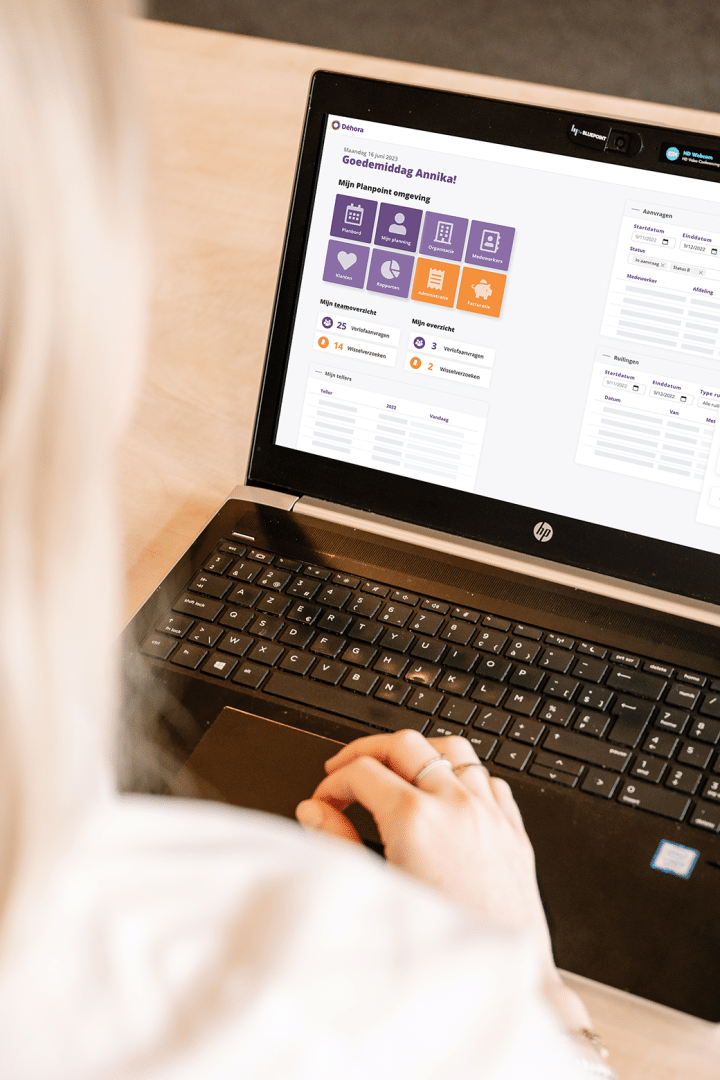

The scheduling of technicians and equipment happens in one modern and clear system. All hours worked and to be worked are in one place. What’s more, staff scheduling in Planpoint is always and everywhere accessible to planners and employees. So everyone is always up to date with new work and changes.

The mobile application of Planpoint is greatly appreciated by technicians. Employees can quickly see which orders they have to carry out for which customer. And with a better overview, planning can be optimized throughout the organization. Since Hilaire Van der Haeghe started using Planpoint, employee involvement has increased significantly. Planning now takes much less time and effort. Entering and loading orders also now runs automatically through a link with Navision.

“The critical capacity of technicians, different planning methodologies, schedules, timing, location, distance … all fused into one watertight and approachable software package. Planpoint is an indispensable handhold.”

Eager to learn more about Planpoint?

Are you looking for new planning or WFM software for your organization? Or do you have a question? Leave your details below and we will get in touch with you.